What we do.

INNOVATIVE CUSTOM DESIGN

With a combined over 100 years experienced in our industry, our engineering staff is the perfect complement to our customers creativity. We are able to assist in the design process of a project with our customers, to help reduce costs, shorten prototype lead-times, and help bring to life complexed innovative ideas.

RAPID PROTOTYPES

Our combination of a stream line process, engineering experience and the use of the same software platform as our customers, allows us to be the industry leader in rapid prototyping. Our turnaround times range from 1 to 5 days depending on complexity. We understand the importance of speed to market, but we also understand that quality is just as important. Without combining the two, our clients will not succeed, and we pride ourselves on meeting our clients lofty expectations.

SPEED TO MARKET

The average lead-time in our factory is 3 weeks. We are able to accomplish such record times without sacrificing quality by using our rapid prototype process as our foundation. Our prototypes are manufactured the same way they will be produced, and follow the same manufacturing processes. This allows our production team to anticipate potential issues and correct them before production starts. At the arrival of a production PO, we are ready to go.

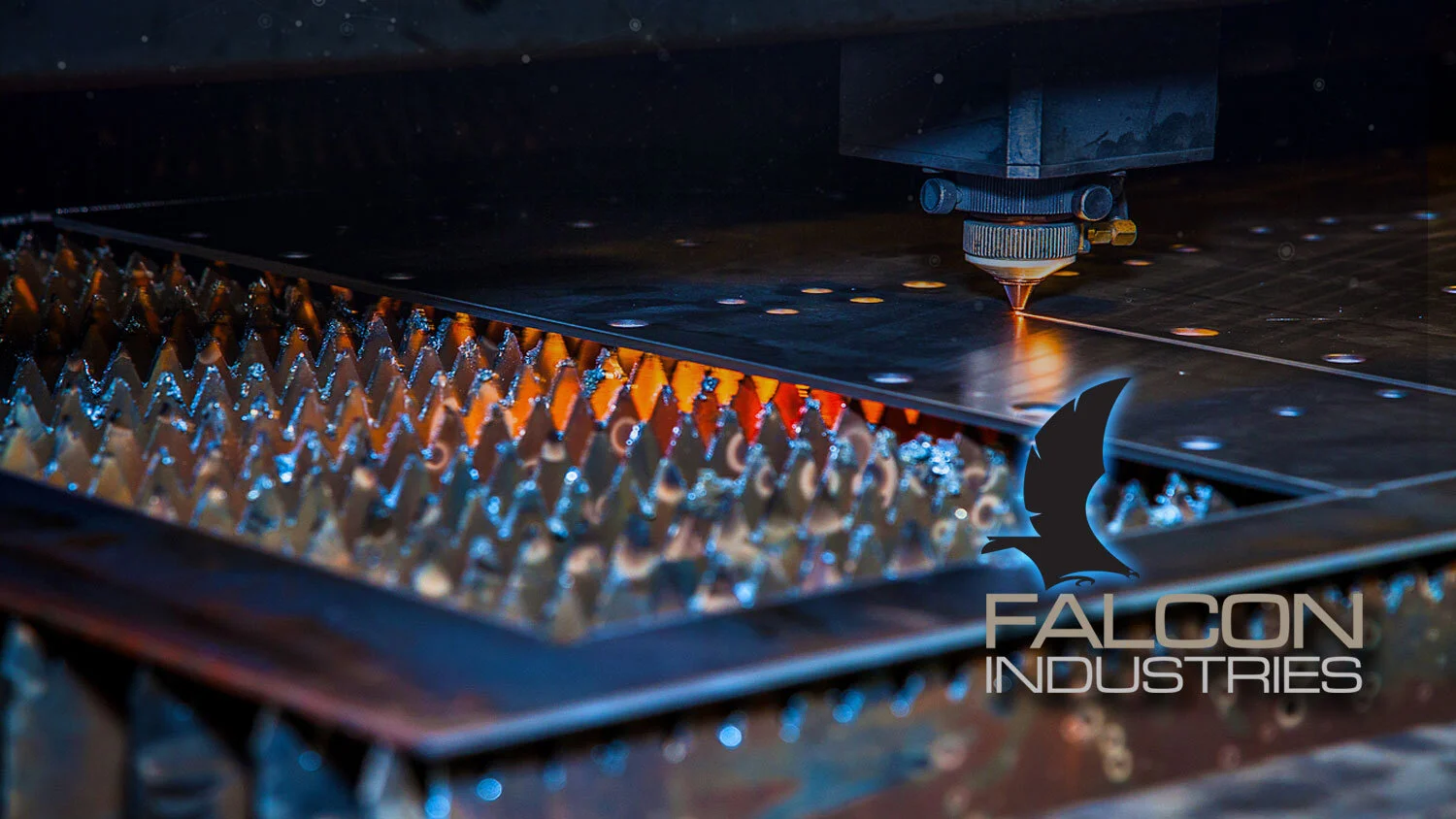

SUPERIOR ENGINEERING & MANUFACTURING

The Falcon engineering staff is a diverse group that understands our industry and its challenges. 90% of our work is custom, as such, it requires out of the box thinking combined with great expertise and ingenuity. We custom make fixtures to manufacture all our work, ensuring accurate repeatability and consistent quality.

CUSTOM FINISHES

With our own in-house powder coating line we are able to control the high level finishes our customers have come to expect. Imagination is the only limiting factor to the array of colors we can provide. Our finishes range from matte, textured to high gloss and can be proudly seen in a wide variety of displays ranging from home goods to high end cosmetics.

UNMATCHED PRODUCT QUALITY

Quality is the hallmark of our business and we take a team approach throughout the organization, starting with engineering and ending when it leaves our facility. As part of our process we meticulously and without exception perform first piece article inspections, and seek pre-production samples approval from our customers. Our personnel monitors all items as they move thru the process, looking for imperfections and ways to improve results.

OVER 21 YEARS OF EXPERIENCE

Our experience has helped our track record and reputation as the best in the business at achieving fast lead times without sacrificing quality. Our engineering and manufacturing capabilities are unparalled. Working with diverse clients and industries gives us the edge over our competitors.

IMPECCABLE CUSTOMER SERVICE

Our Project Management group is responsible for every aspect of a project the minute production starts. They provide all pertinent information related to the project to our customers, and can answer any questions regarding progress of production and anticipated finish dates. We know how important it is to have a single knowledgable point of contact, and our team shows it with their performance.

CUSTOM ASSEMBLY & PACKOUTS

Falcon assembles, packs and ships a wide variety of projects varying from the simplest of displays to more sophisticated units. This includes assembly of LCD’s, MP3 Players, LED Lighting, etc. We pride ourselves on being able to tackle projects big and small, and being a ONE STOP SHOP for all of our clients’ needs. We offer turn-key solutions and service to our customers allowing their products to be shipped directly from our facility.